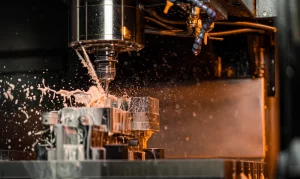

In the realm of industrial workplaces, optimizing productivity and employee well-being is paramount. Industrial metalworking solutions are key in meeting the diverse needs of industrial workers. By highlighting the benefits of these solutions, a shift towards workplace wellness unfolds.

From improving safety measures to boosting efficiency, industrial metalworking systems impact various industrial sectors. Exploring the advantages they offer reveals a narrative of empowerment and progress, showcasing their potential in fostering a culture of well-being for industrial workers.

Key Takeaways

- Automation and robotics can handle dangerous tasks, enhancing worker safety and reducing accidents.

- Implementing safety features like sensors, emergency stop buttons, and protective barriers is crucial for maintaining a secure work environment.

- Efficiency in metalworking processes can be boosted through automation, real-time monitoring, and high-performance cutting tools.

- Prioritizing worker well-being by minimizing physical strain, improving air quality, and promoting stress-free workspaces leads to enhanced operational efficiency.

Challenges Faced by Industrial Workers

Facing a myriad of obstacles in their daily tasks, industrial workers encounter a range of challenges that demand strategic solutions and a keen eye for efficiency. One of the primary challenges faced by industrial workers is ensuring workplace safety. With heavy machinery, potentially hazardous materials, and high-risk tasks, the risk of accidents is significant. Implementing strict safety protocols, providing proper training, and ensuring equipment maintenance are crucial in mitigating these risks.

Another challenge is maintaining productivity amidst fluctuating demands and deadlines. Industrial workers often face tight production schedules and the pressure to meet quotas. This requires efficient time management, streamlined processes, and effective communication among team members to ensure smooth operations.

Additionally, the physical demands of industrial work can lead to fatigue and strain on the body. Workers must find ways to maintain their health and well-being to perform optimally. Implementing ergonomic workstations, promoting regular breaks, and offering wellness programs can help alleviate these challenges.

Importance of Industrial Metalworking Solutions

Industrial metalworking solutions play a vital role in ensuring optimal performance and safety for workers in industrial settings. Here are three key reasons highlighting the importance of these solutions:

- Precision Machining: Industrial metalworking process enable precision machining processes, ensuring accurate and consistent production of metal components. This precision is essential for maintaining quality standards and meeting industry specifications, ultimately enhancing overall efficiency in manufacturing operations.

- Safety Measures: Industrial metalworking systems often incorporate safety features such as machine guards, emergency stop buttons, and safety interlocks to protect workers from potential hazards. By prioritizing safety in metalworking processes, these solutions help create a secure work environment and reduce the risk of accidents or injuries.

- Increased Productivity: By streamlining metalworking processes and optimizing workflow efficiency, industrial metalworking solutions contribute to increased productivity levels. Whether through automation, advanced tools, or efficient workstations, these solutions enable industrial workers to accomplish tasks more effectively, leading to enhanced productivity within the workplace.

Enhancing Safety in Metalworking Environments

Industries metalworking solution not only optimize productivity and precision in manufacturing operations but also play a critical role in enhancing safety standards within metalworking environments. Safety is paramount in metalworking due to the inherent risks involved in working with heavy machinery, sharp tools, and potentially hazardous materials. Implementing industrial metalworking solutions can significantly reduce the likelihood of workplace accidents and injuries.

One key way industrial metalworking process enhance safety is by introducing automation and robotics into the manufacturing process. Automated systems can handle tasks that are dangerous for human workers, such as lifting heavy materials or operating equipment in high-temperature environments. By delegating these tasks to machines, the risk of accidents caused by human error or fatigue is minimized.

Furthermore, industrial metalworking systems often include advanced safety features such as sensors, emergency stop buttons, and protective barriers. These features help create a safer work environment by alerting workers to potential hazards and providing mechanisms to quickly halt operations in case of an emergency. Overall, investing in industrial metalworking systems not only boosts productivity but also ensures the well-being of workers in metalworking environments.

Boosting Efficiency Through Metalworking Solutions

Implementing cutting-edge metalworking solutions revolutionizes operational efficiency in manufacturing environments. By leveraging advanced technologies and techniques, industrial workers can streamline processes, optimize production, and ultimately enhance overall productivity.

Here are three key ways in which metalworking solutions can boost efficiency:

- Automation Integration: Incorporating automation into metalworking processes can significantly reduce manual labor, minimize human error, and expedite production cycles. Automated systems can handle repetitive tasks with precision and speed, allowing workers to focus on more complex operations.

- Real-Time Monitoring: Utilizing monitoring systems enables real-time tracking of production metrics, machine performance, and quality control parameters. This data-driven approach allows for proactive decision-making, timely adjustments, and continuous improvement efforts to maximize efficiency.

- Tooling Optimization: Implementing advanced tooling technologies, such as high-performance cutting tools and efficient machining strategies, can enhance precision, speed, and consistency in metalworking operations. Well-maintained and optimized tools contribute to smoother workflows, reduced downtime, and higher output quality.

Promoting Well-Being With Industrial Metalworking Solutions

Metalworking solutions not only enhance operational efficiency but also play a vital role in promoting the well-being of industrial workers through optimized processes and improved working conditions. By utilizing advanced industrial metalworking solutions, companies can create a safer and more ergonomic work environment for their employees.

One significant aspect of promoting well-being with industries metalworking solutions is the reduction of manual labor and repetitive tasks. Automation and robotics in metalworking processes can help minimize the physical strain on workers, reducing the risk of injuries and long-term musculoskeletal issues. Additionally, the implementation of efficient ventilation systems in metalworking facilities can improve air quality, reducing exposure to harmful fumes and particles that could adversely affect workers’ health.

Moreover, industrial metalworking systems can contribute to a more organized and tidy workspace, further enhancing the well-being of employees. Proper tool storage, waste management systems, and streamlined workflows not only increase productivity but also create a pleasant and stress-free atmosphere for workers. Overall, investing in industries metalworking solutions not only boosts operational efficiency but also prioritizes the health and well-being of industrial workers.

Frequently Asked Questions

Can Industrial Metalworking Solutions Help Reduce Workplace Injuries in Industrial Settings?

Industrial metalworking solutions play a crucial role in reducing workplace injuries in industrial settings. Through advanced machinery, safety protocols, and ergonomic designs, these solutions enhance worker safety, minimize accidents, and promote a healthier work environment.

How Do Industrial Metalworking Solutions Contribute to the Overall Productivity of Industrial Workers?

Industrial metalworking solutions enhance productivity by streamlining processes, improving precision, and reducing downtime. Advanced machinery and tools optimize workflow, ensuring efficient production. Well-maintained equipment and ergonomic designs contribute to a safer and more productive work environment.

What Are the Key Features to Look for When Choosing Industrial Metalworking Solutions for a Specific Industrial Setting?

When choosing industries metalworking solutions for a specific setting, key features to consider include precision machining capabilities, durability, compatibility with existing equipment, safety features, ease of maintenance, energy efficiency, and the provider’s reputation for quality and service.

Are There Any Specific Training Programs Available to Help Industrial Workers Effectively Use Metalworking Solutions?

Training programs tailored for industrial workers to effectively utilize metalworking solutions are essential. These programs cover safety protocols, equipment operation, maintenance procedures, and troubleshooting techniques. Ensuring proper training enhances productivity, reduces errors, and promotes a safer work environment.

How Do Industrial Metalworking Solutions Impact the Mental Well-Being of Industrial Workers in High-Stress Environments?

Industrial metalworking solutions can positively impact the mental well-being of industrial workers in high-stress environments by enhancing efficiency, reducing physical strain, and promoting safer work practices. These solutions contribute to a healthier and more productive work environment.

Conclusion

In conclusion, industrial metalworking solutions play a crucial role in addressing the challenges faced by industrial workers. These solutions enhance safety, boost efficiency, and promote overall well-being in the workplace. By integrating innovative technologies and approaches, organizations can create a conducive work environment that prioritizes employee health and productivity. The transformative potential of industrial metalworking systems in promoting wellness at work highlights their significance as a strategic investment for industrial sectors.

You May Also Like: